ProfilePrint’s AI tools work together to support your quality decisions throughout your operations. Each tool serves multiple purposes so you can adapt them to your specific needs.

Assess ingredient quality with AI models

Buy Better • Sell Better

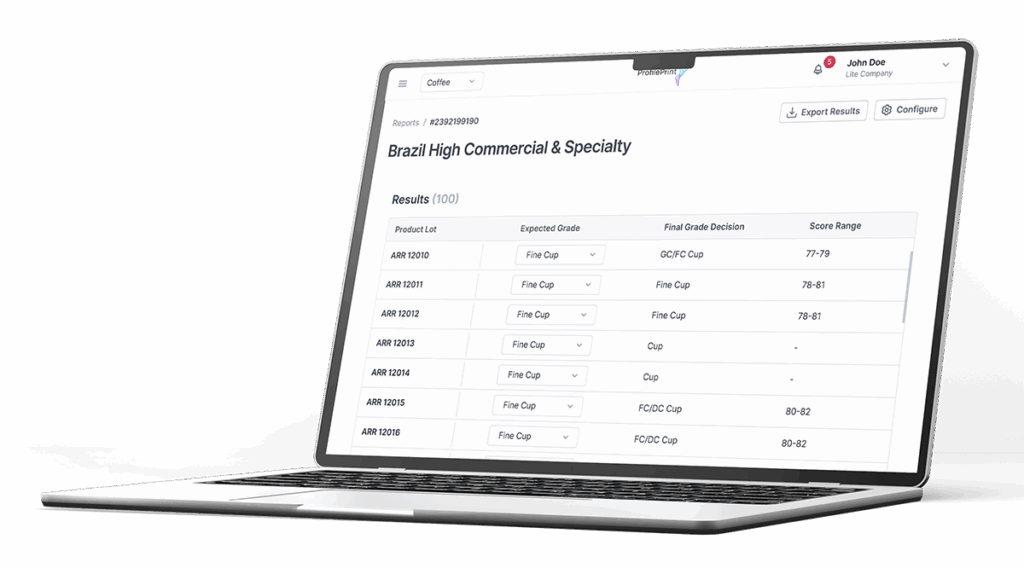

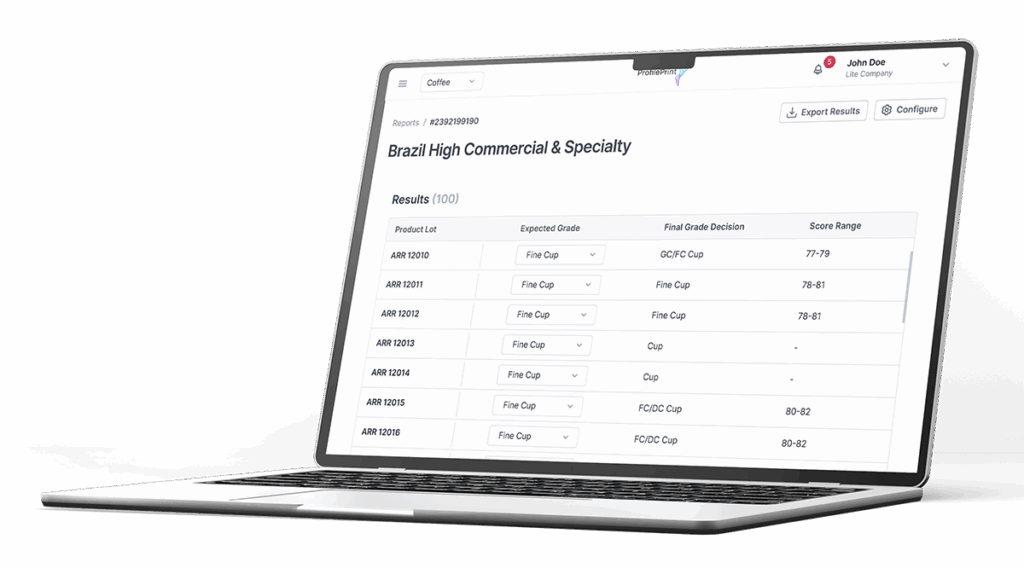

Ready-to-use quality assessment for immediate insights

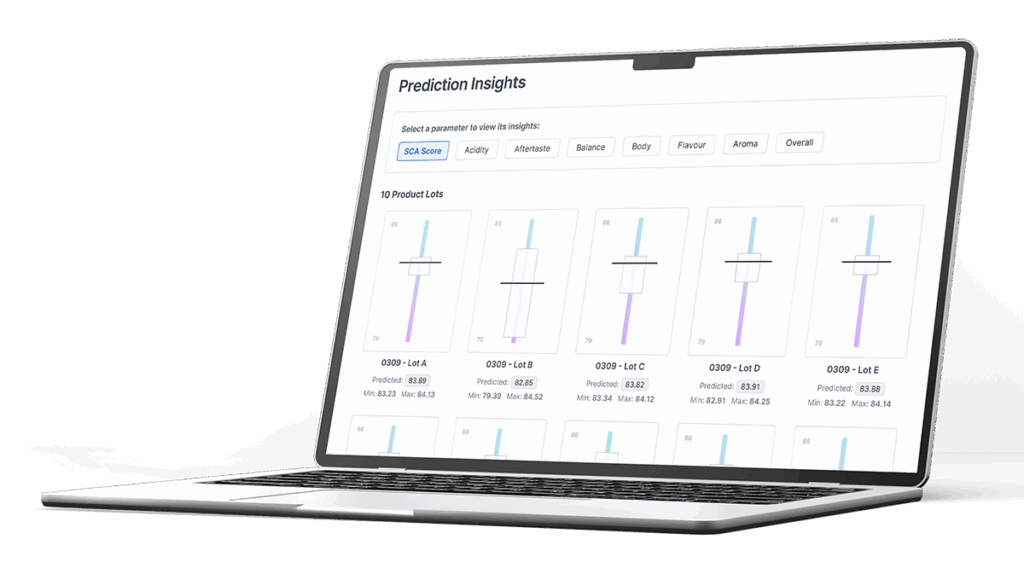

Use pre-built models trained on extensive industry data to predict quality scores, screen for flavour profiles or defects, and evaluate against industry benchmarks.

Available models for coffee

Specialty Arabica Green Bean (SAGB)

Our most popular model, trained on 28,000+ coffee samples. Predicts SCA scores, moisture levels, and flavour notes

Robusta Fine Cup

Predicts quality scores and processing methods for Robusta coffee

Non-Visual Defects (NVD)

Detects defective cups in Brazil, Colombia and Honduras coffee samples

Available models for tea

Black Tea Sensory BP1

Predicts sensory characteristics and quality categories for Broken Pekoe (BP1) CTC tea grade, including tea infusion and tea liquor

Black Tea Sensory PF1

Predicts sensory characteristics and quality categories for Pekoe Fannings (PF1) CTC tea grade, including tea infusion and tea liquor

Buy Better

Sell Better

Screen suppliers and assess quality before purchasing, reducing the risk of purchasing ingredients that don’t meet your standards

Verify inventory quality and support pricing discussions with objective data, helping you maximise value and meet customer expectations

Buy Better • Sell Better

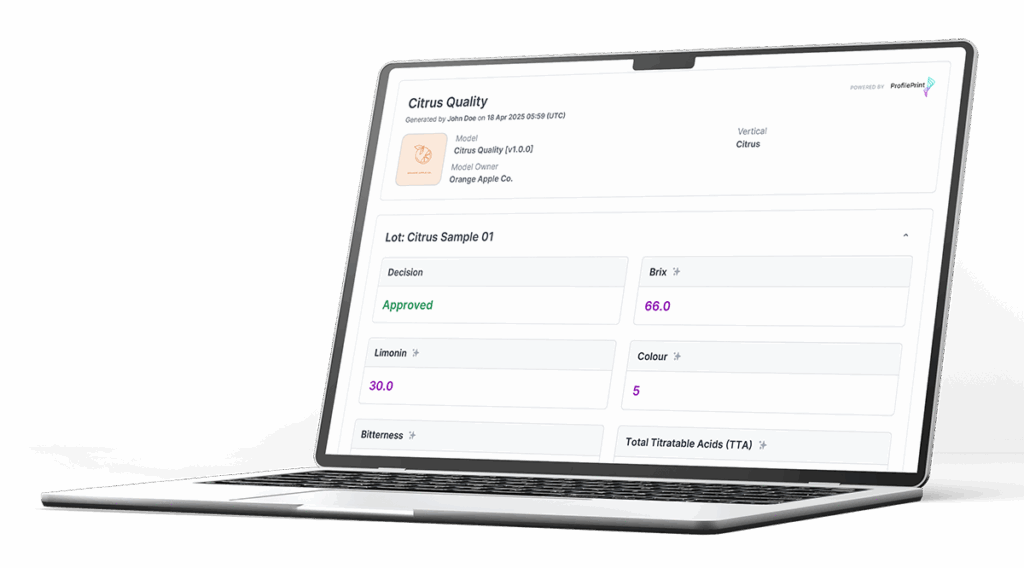

Custom assessment aligned with your specific standards

Every business has unique quality requirements. Build custom models directly on the platform to assess ingredients based on your exact criteria, improving speed and accuracy in your decisions. Refine your models over time as your needs evolve, and share them with suppliers or buyers to align on quality requirements and standards, creating transparency across your partnerships.

What you can build:

Profile

Predict numerical scores for sensory attributes, moisture levels, or quality scores etc.

Classify

Sort by grade, origin, pass/fail, or detect adulteration etc.

Buy Better

Sell Better

Screen suppliers based on exactly what matters to your purchasing decisions, improving speed and accuracy in ingredient assessment

Verify products meet customer specifications before shipment, reducing rejection risk and building stronger customer relationships

Buy Better • Sell Better

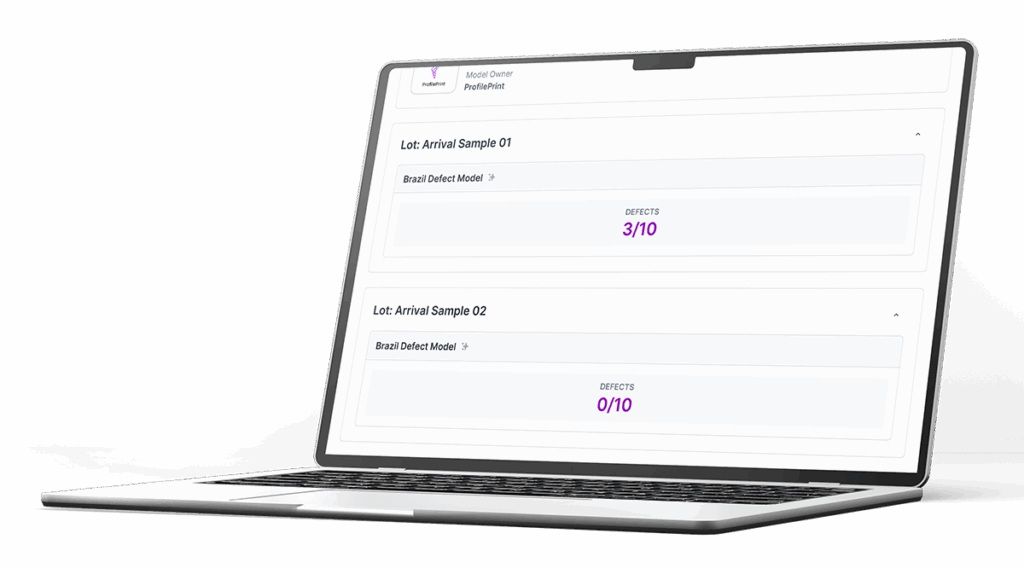

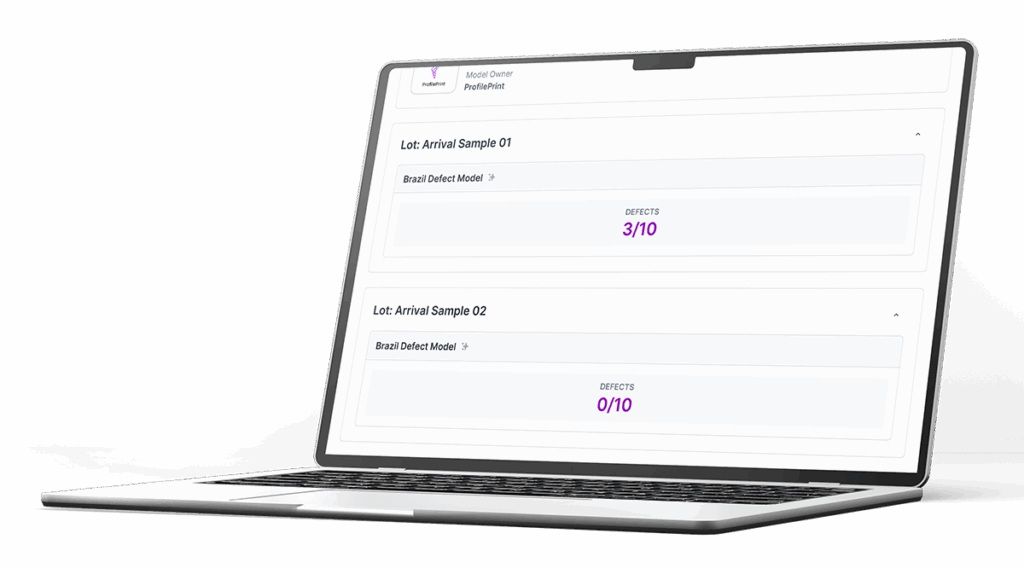

Detect sensory defects without any processing

Screen ingredients for sensory defects instantly with digital fingerprints, without having to physically evaluate the ingredient. Process high volumes quickly while maintaining consistency, so you can make decisions before investing in processing or shipment.

Buy Better

Sell Better

Understand the defect levels in lots before purchasing, so you know exactly what you’re getting and how much to pay

Assess defect levels to price your lots appropriately and demonstrate transparency with buyers about what they’re receiving

Buy Better • Sell Better

Calibrate pre-built models to your specific requirements

Adapt existing models to match your quality standards, delivering faster deployment while maintaining established model reliability. This bridges the gap between Plug-n-Play convenience and fully custom solutions, so you can start assessing quality according to your requirements within weeks.

Buy Better

Sell Better

Screen against your specific purchasing criteria quickly, accelerating supplier evaluation

Align with different customer requirements efficiently, helping you respond faster to varied buyer specifications

Buy Better • Sell Better

Ready-to-use quality assessment for immediate insights

Use pre-built models trained on extensive industry data to predict quality scores, screen for flavour profiles or defects, and evaluate against industry benchmarks.

Available models for coffee

Specialty Arabica Green Bean (SAGB)

Our most popular model, trained on 28,000+ coffee samples. Predicts SCA scores, moisture levels, and flavour notes

Robusta Fine Cup

Predicts quality scores and processing methods for Robusta coffee

Non-Visual Defects (NVD)

Detects defective cups in Brazil, Colombia and Honduras coffee samples

Available models for tea

Black Tea Sensory BP1

Predicts sensory characteristics and quality categories for Broken Pekoe (BP1) CTC tea grade, including tea infusion and tea liquor

Black Tea Sensory PF1

Predicts sensory characteristics and quality categories for Pekoe Fannings (PF1) CTC tea grade, including tea infusion and tea liquor

Buy Better

Screen suppliers and assess quality before purchasing, reducing the risk of purchasing ingredients that don’t meet your standards

Sell Better

Verify inventory quality and support pricing discussions with objective data, helping you maximise value and meet customer expectations

Buy Better • Sell Better

Custom assessment aligned with your specific standards

Every business has unique quality requirements. Build custom models directly on the platform to assess ingredients based on your exact criteria, improving speed and accuracy in your decisions. Refine your models over time as your needs evolve, and share them with suppliers or buyers to align on quality requirements and standards, creating transparency across your partnerships.

What you can build:

Profile

Predict numerical scores for sensory attributes, moisture levels, or quality scores etc.

Classify

Sort by grade, origin, pass/fail, or detect adulteration etc.

Buy Better

Screen suppliers based on exactly what matters to your purchasing decisions, improving speed and accuracy in ingredient assessment

Sell Better

Verify products meet customer specifications before shipment, reducing rejection risk and building stronger customer relationships

Buy Better • Sell Better

Detect sensory defects without any processing

Screen ingredients for sensory defects instantly with digital fingerprints, without having to physically evaluate the ingredient. Process high volumes quickly while maintaining consistency, so you can make decisions before investing in processing or shipment.

Buy Better

Understand the defect levels in lots before purchasing, so you know exactly what you’re getting and how much to pay

Sell Better

Understand the defect levels in lots before purchasing, so you know exactly what you’re getting and how much to pay

Buy Better • Sell Better

Calibrate pre-built models to your specific requirements

Adapt existing models to match your quality standards, delivering faster deployment while maintaining established model reliability. This bridges the gap between Plug-n-Play convenience and fully custom solutions, so you can start assessing quality according to your requirements within weeks.

Buy Better

Screen against your specific purchasing criteria quickly, accelerating supplier evaluation

Sell Better

Align with different customer requirements efficiently, helping you respond faster to varied buyer specifications

Make better decisions with AI-powered insights and recommendations

Buy Better • Sell Better • Ensure Consistency

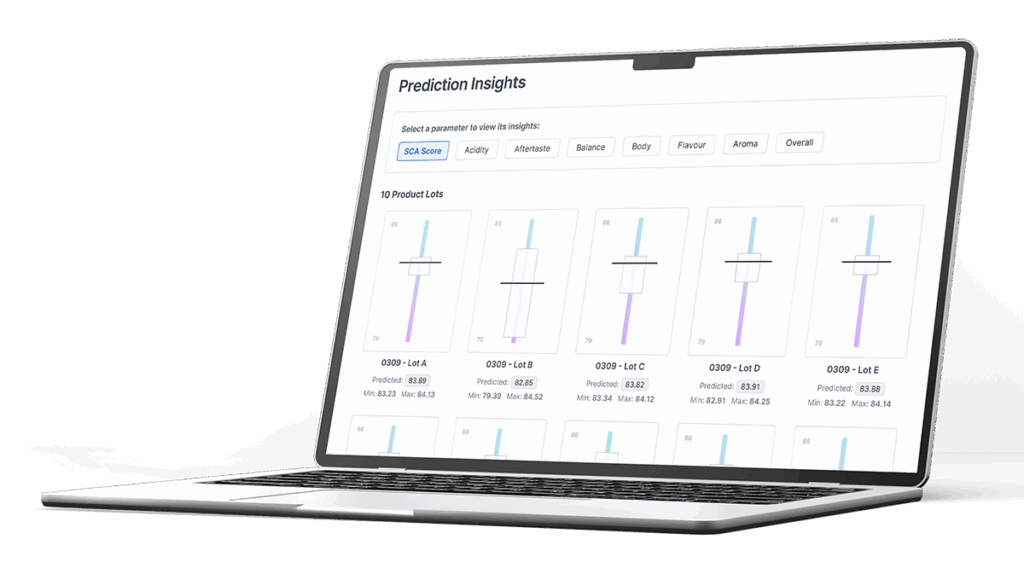

Understanding ingredient consistency

Not all ingredients are uniform. Fingerprint Insights reveals the consistency within each lot, helping you understand the variability in your ingredients before making critical decisions.

When AI predictions differ from expert assessments, Fingerprint Insights often shows why. Ingredient variation directly influences AI predictions, so understanding lot uniformity gives you deeper insight into the AI’s outputs and helps you identify which predictions need human review.

Buy Better

Sell Better

Ensure Consistency

Make informed purchasing decisions by understanding ingredient uniformity, reducing the risk of buying inconsistent lots

Demonstrate lot uniformity to customers with objective data, building trust and strengthening customer relationships

Focus your quality team’s attention on lots with higher variability that need closer inspection, and make informed decisions about blending or processing non-uniform ingredients

Buy Better • Sell Better • Ensure Consistency

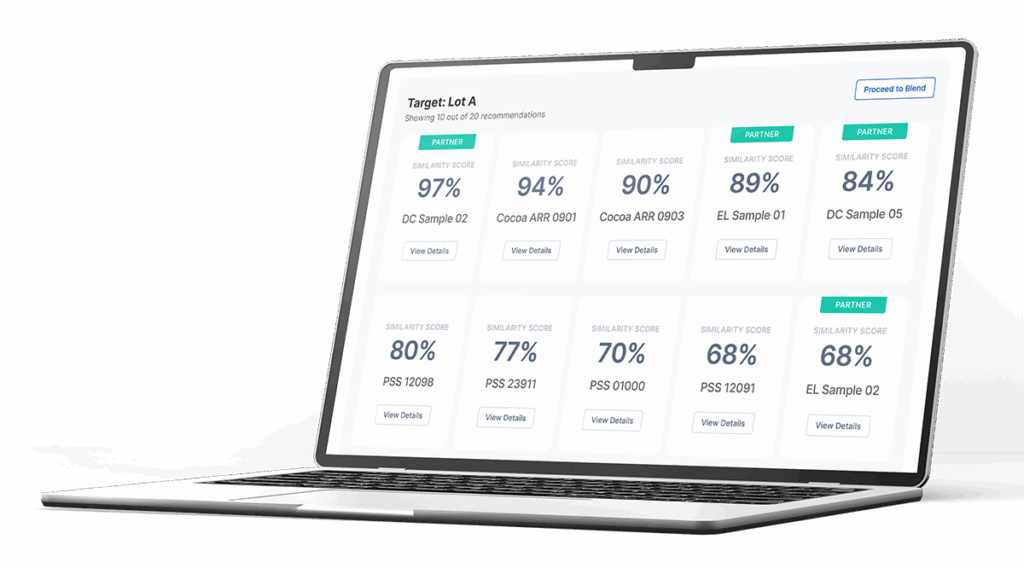

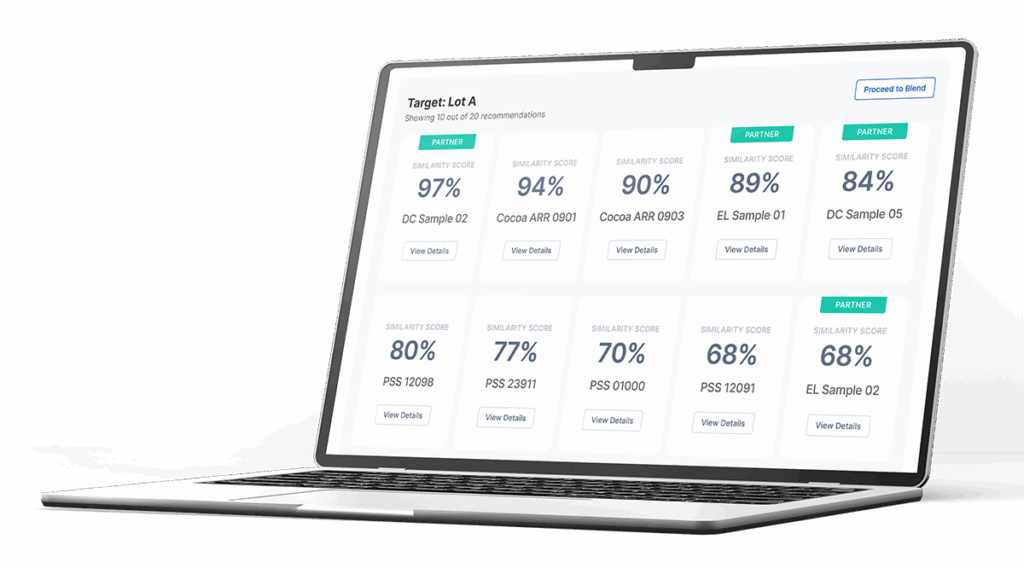

Find ingredients that meet your target or to verify consistency

Facing supply disruptions or need to match inventory to customer specifications? Match searches your inventory or supplier options and compares them against your target requirements, revealing alternatives you might not have considered.

This versatile tool helps you discover new suppliers, identify which lots best serve specific customers, or verify that incoming ingredients meet your established standards.

Buy Better

Sell Better

Ensure Consistency

Discover alternative suppliers when facing disruptions, reducing sourcing time while maintaining your quality standards

Identify which inventory lots best match a customer’s target, reducing sales cycle and helping you serve customers more effectively

Verify incoming ingredients meet a previous batch or target standard, maintaining quality at critical control points

Sell Better

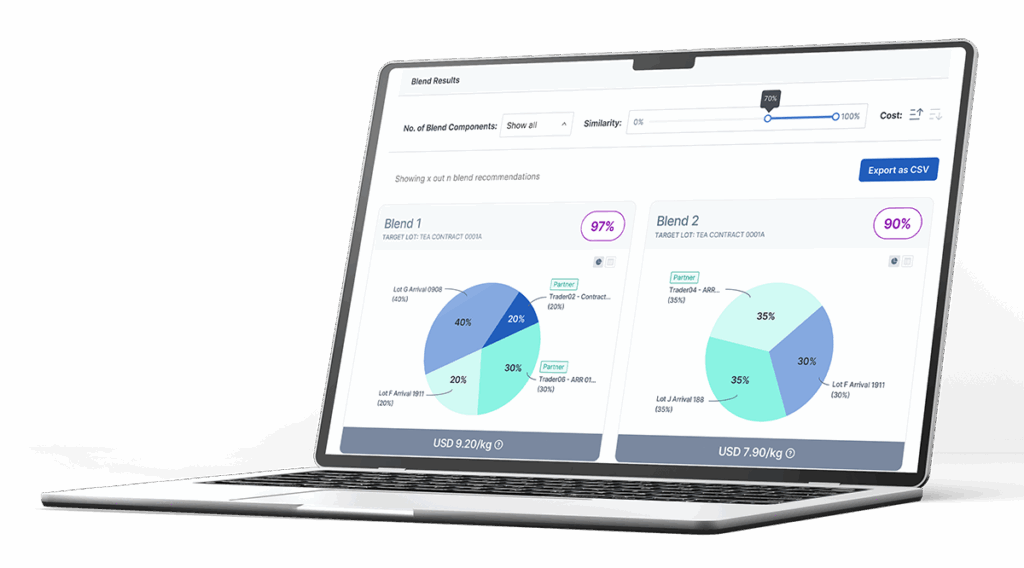

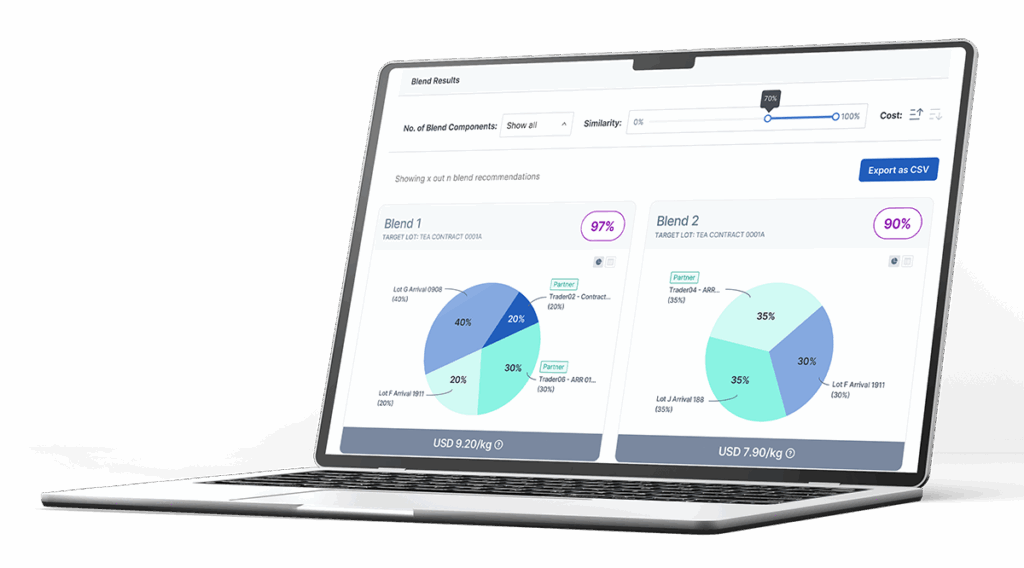

Optimise blends with AI assistance

Take the guesswork out of blend development. Blend analyses your target profile and suggests optimal combinations from your available inventory, balancing both quality and cost considerations. This helps you create products more quickly, before your experts test and approve the final blend.

Sell Better

Create products that meet customer specifications while optimising margins, helping you respond faster to market demands

Buy Better • Sell Better • Ensure Consistency

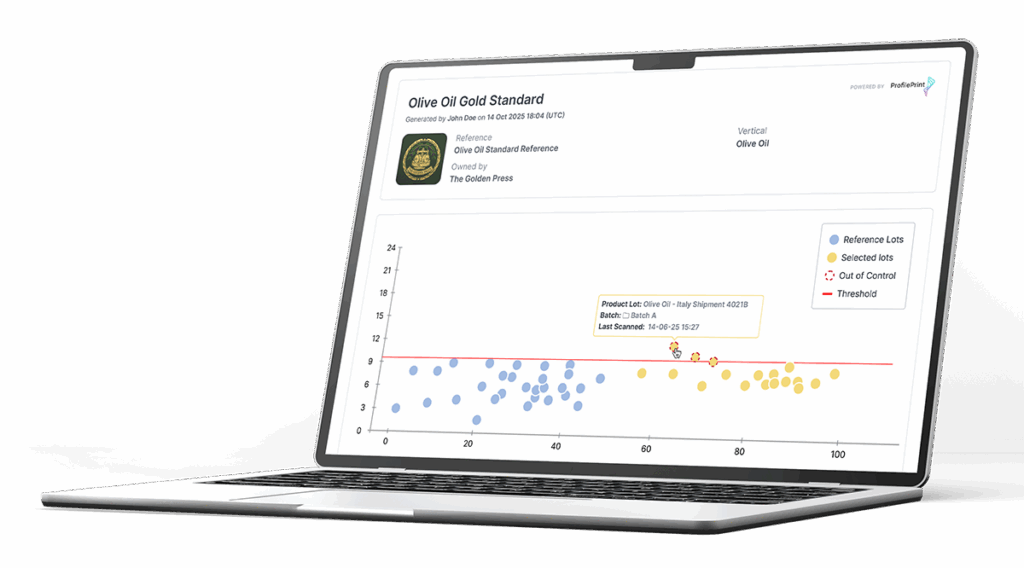

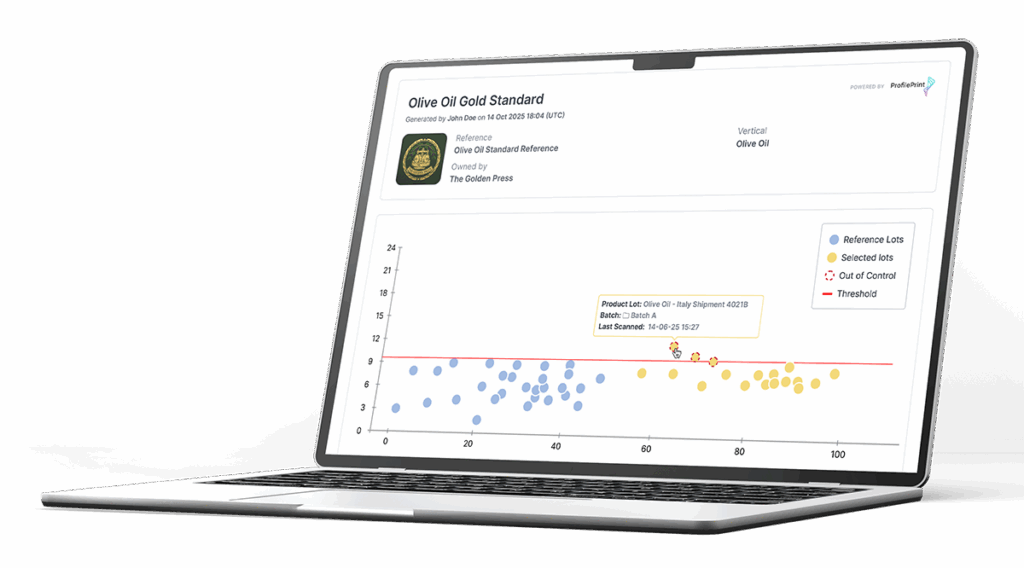

Track quality variations throughout your operations

Monitor detects variations and inconsistencies across your batches. When a lot falls outside your acceptable ranges, you receive early warnings so you can address problems proactively.

Ensure Consistency

Catch issues before they escalate into costly product recalls or waste, helping you maintain consistent quality and protect your reputation

Buy Better • Sell Better • Ensure Consistency

Understanding ingredient consistency

Not all ingredients are uniform. Fingerprint Insights reveals the consistency within each lot, helping you understand the variability in your ingredients before making critical decisions.

When AI predictions differ from expert assessments, Fingerprint Insights often shows why. Ingredient variation directly influences AI predictions, so understanding lot uniformity gives you deeper insight into the AI’s outputs and helps you identify which predictions need human review.

Buy Better

Make informed purchasing decisions by understanding ingredient uniformity, reducing the risk of buying inconsistent lots

Sell Better

Demonstrate lot uniformity to customers with objective data, building trust and strengthening customer relationships

Ensure Consistency

Focus your quality team’s attention on lots with higher variability that need closer inspection, and make informed decisions about blending or processing non-uniform ingredients

Buy Better • Sell Better • Ensure Consistency

Find ingredients that meet your target or to verify consistency

Facing supply disruptions or need to match inventory to customer specifications? Match searches your inventory or supplier options and compares them against your target requirements, revealing alternatives you might not have considered.

This versatile tool helps you discover new suppliers, identify which lots best serve specific customers, or verify that incoming ingredients meet your established standards.

Buy Better

Discover alternative suppliers when facing disruptions, reducing sourcing time while maintaining your quality standards

Sell Better

Identify which inventory lots best match a customer’s target, reducing sales cycle and helping you serve customers more effectively

Ensure Consistency

Verify incoming ingredients meet a previous batch or target standard, maintaining quality at critical control points

Sell Better

Optimise blends with AI assistance

Take the guesswork out of blend development. Blend analyses your target profile and suggests optimal combinations from your available inventory, balancing both quality and cost considerations. This helps you create products more quickly, before your experts test and approve the final blend.

Sell Better

Create products that meet customer specifications while optimising margins, helping you respond faster to market demands

Buy Better • Sell Better • Ensure Consistency

Track quality variations throughout your operations

Monitor detects variations and inconsistencies across your batches. When a lot falls outside your acceptable ranges, you receive early warnings so you can address problems proactively.

Ensure Consistency

Catch issues before they escalate into costly product recalls or waste, helping you maintain consistent quality and protect your reputation