SUCCESS STORY

Early Rancidity Detection

Preventing costly quality failures

Challenge

Our client, an olive oil producer, faced a quality control dilemma that many food manufacturers struggle with: detecting rancidity before it impacts their products and reputation. Traditional methods like lab analysis or sensory evaluation can be time-consuming and expensive, making routine screening impractical.

Solution

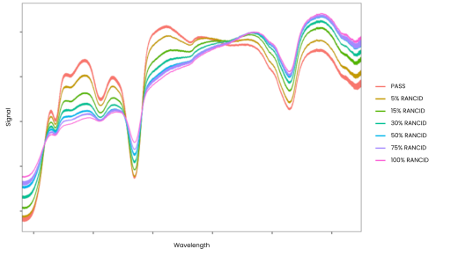

We used our range of transflectance dishes crafted specifically for liquid analysis to maximise accuracy while minimising signal noise.

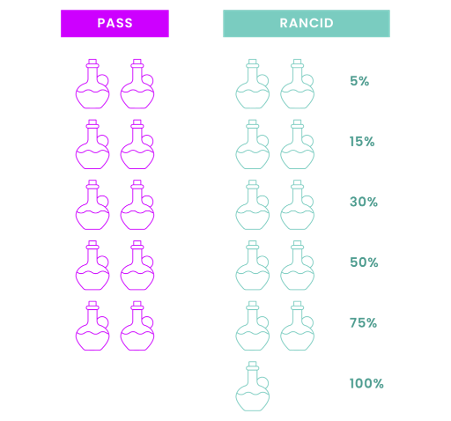

We trained the AI model on 80% of the samples to recognise patterns between “Pass” and “Rancid” oil, then validated it on the remaining blind samples. ProfilePrint was able to capture the unique chemical fingerprint of each sample, with varying levels of intensity across the captured wavelengths, and achieved 100% perfect detection.

What this means for your business

ProfilePrint now provides this olive oil producer with reliable quality screening, enabling them to:

- Achieve rancidity detection to rapidly distinguish between fresh and rancid samples

- Make faster quality decisions getting immediate insights to maintain production schedules

- Prevent costly quality issues by catching them before they impact entire production batches

Is ProfilePrint for you?

Let us see how we can help you leverage AI for your business.

Speak to a member of our team today.