Managing Supply Chain Disruptions with AI

Ensuring Quality Consistency Across Multiple Suppliers During Market Volatility

Managing Supply Chain Disruptions with AI

Ensuring Quality Consistency Across Multiple Suppliers During Market Volatility

Challenge

Global citrus production faces mounting pressure from environmental factors, creating supply shortages and driving up costs across the industry. When primary suppliers face disruptions, beverage companies must quickly source from alternative suppliers to maintain production volumes. This creates a critical challenge: how do you ensure consistent quality when working with new suppliers under time pressure?

Traditional testing methods for key quality parameters like Brix, Limonin, colour and Total Titratable Acids (TTA) can take days and require costly laboratory analysis. During supply disruptions, companies need answers fast to make confident sourcing decisions and avoid production delays.

Solution: AI-Powered Multi-Parameter Quality Assessment

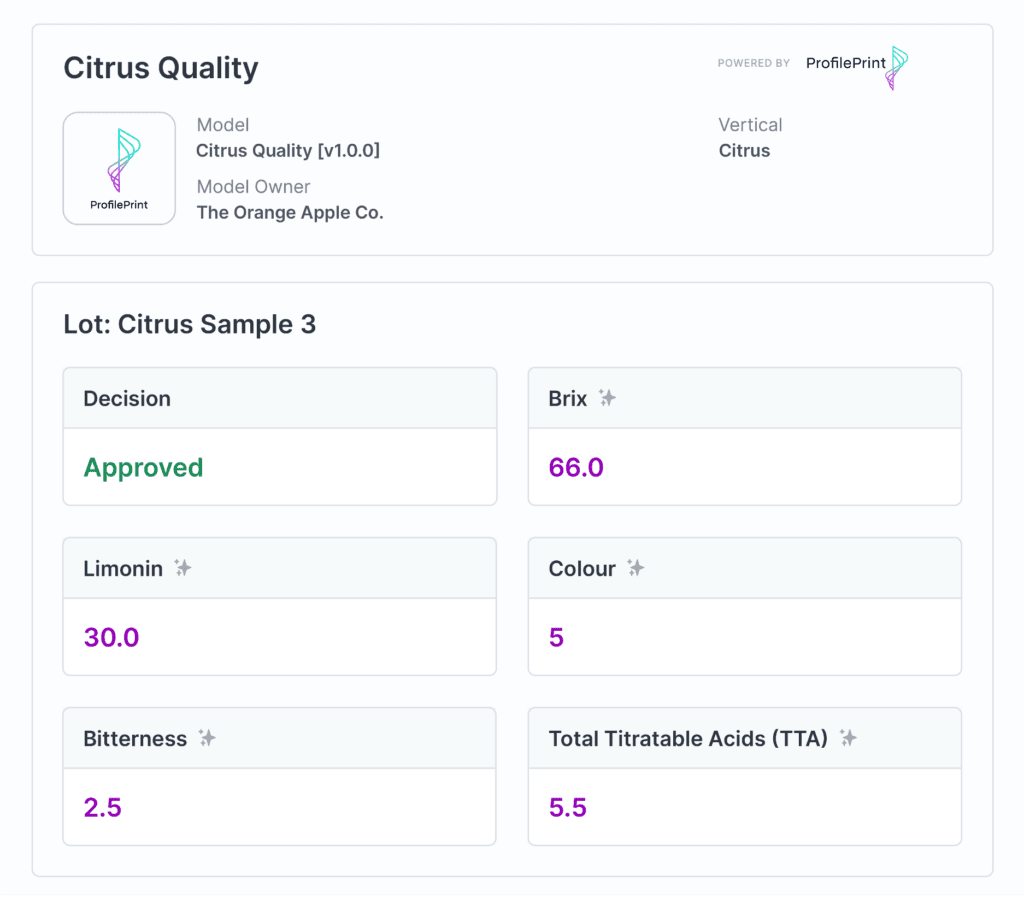

We partnered with a leading beverage company to help their R&D team streamline quality assessment and manage lab workload more efficiently. In six months, we collected 140 digital fingerprints of citrus samples with ProfilePrint’s analyser, while their team provided the chemical analysis data needed to train and validate models for Brix, Limonin, colour and TTA.

The results showed less than 15% error across all parameters, meeting the team’s success criteria for quality assessment. The image displays ProfilePrint’s quality report, which indicates the predictions for each quality parameter and the resultant recommendation for a specific citrus sample.

While ProfilePrint screens majority of the citrus samples, the model flags samples it is less confident about. These are typically samples the AI hasn’t been trained to recognise. For these flagged samples, manual evaluations such as lab tests take over. This significantly reduces the manual evaluation workload and also ensures the model is continually trained with the latest assessments from lab tests, which in turn improves its confidence in future quality predictions.

Today, ProfilePrint helps beverage companies optimise their quality teams’ processes and maintain their standards while adapting quickly to supply chain challenges.

Results

- Faster Quality Decisions: ProfilePrint can generate predictions for key parameters within seconds

Confident Alternative Sourcing: ProfilePrint helps our clients quickly assess quality across multiple suppliers, ensuring new sources meet internal standards before committing to purchases

- Cost Savings: Reduce lab testing requirements for initial screening, saving both time and money while maintaining quality assurance

ProfilePrint offers beverage companies a practical solution for managing supply chain volatility. Our technology enhances your team’s expertise, giving you the data needed to make confident sourcing decisions when facing unexpected supply disruptions.