The Solution

AI Tools

The Solution

AI Tools

READY-TO-USE AI TOOLS

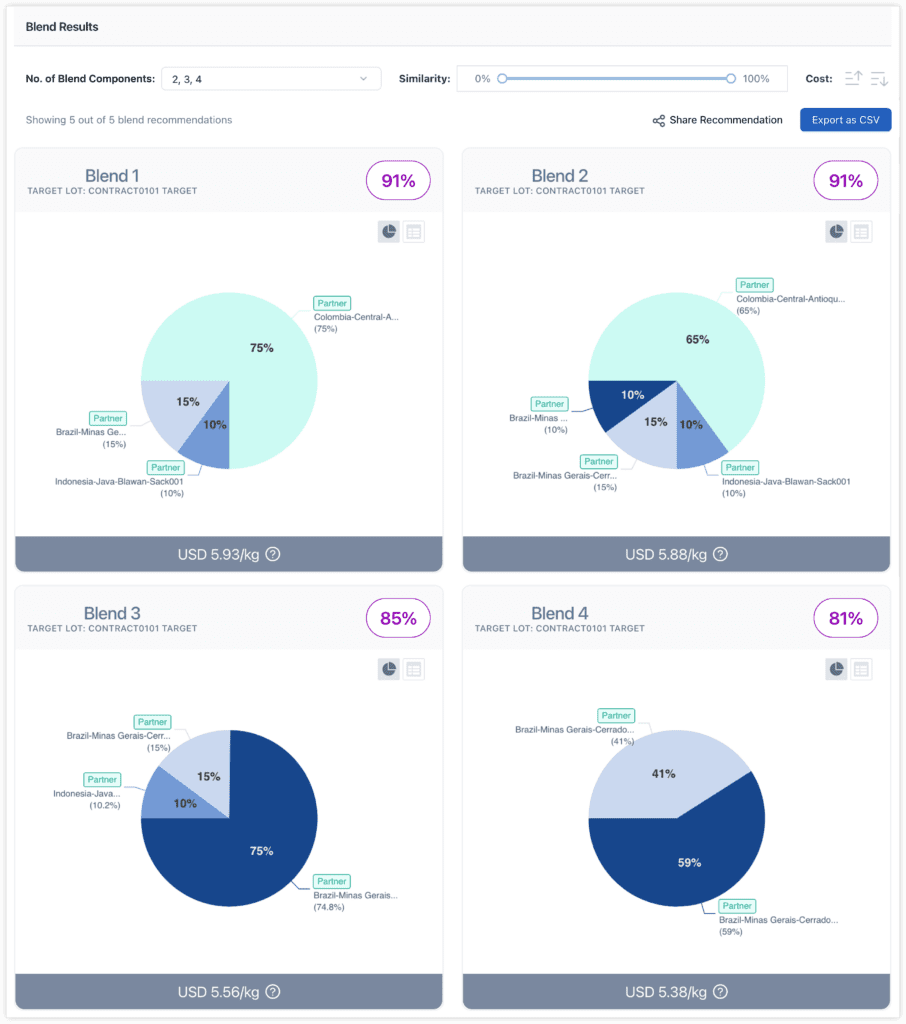

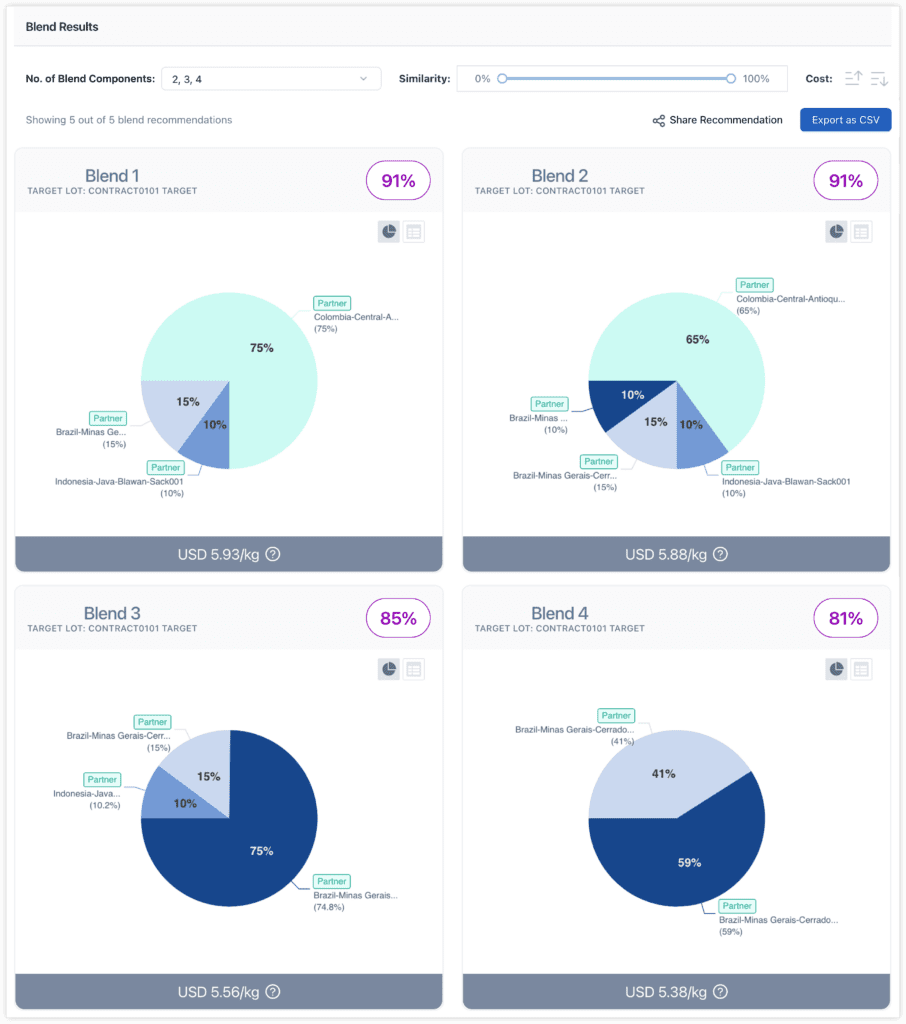

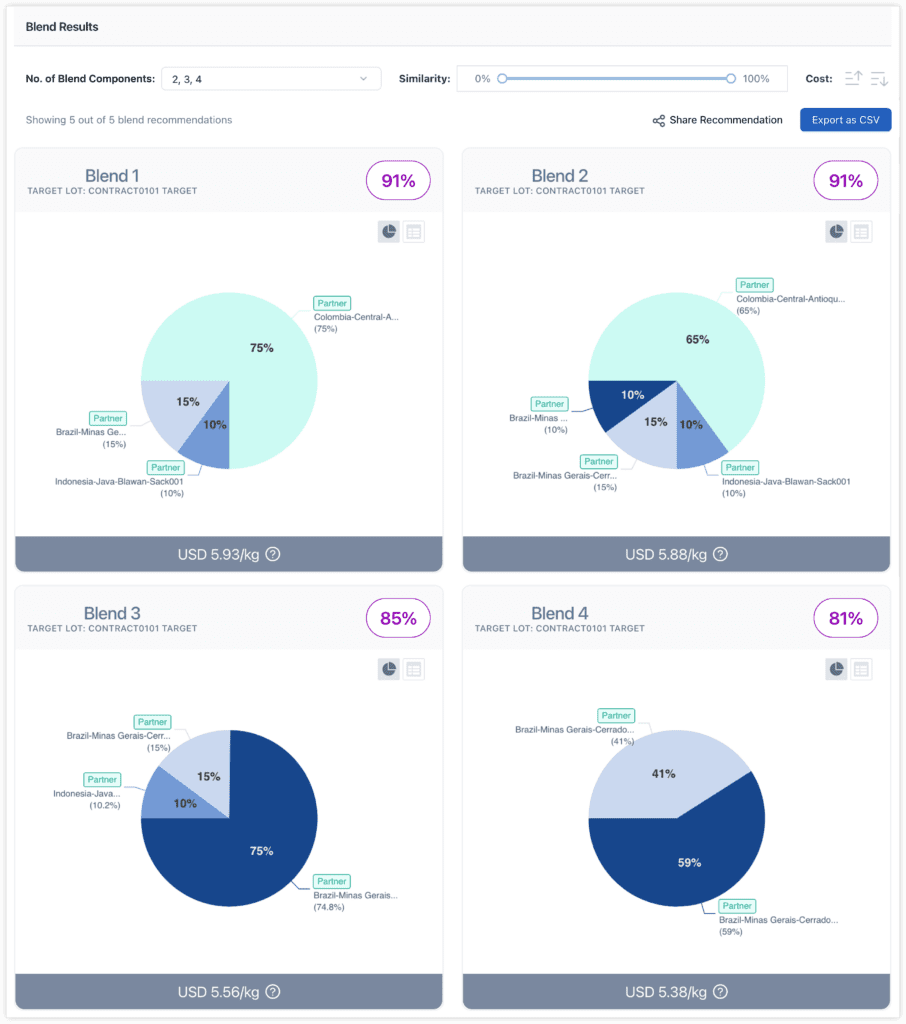

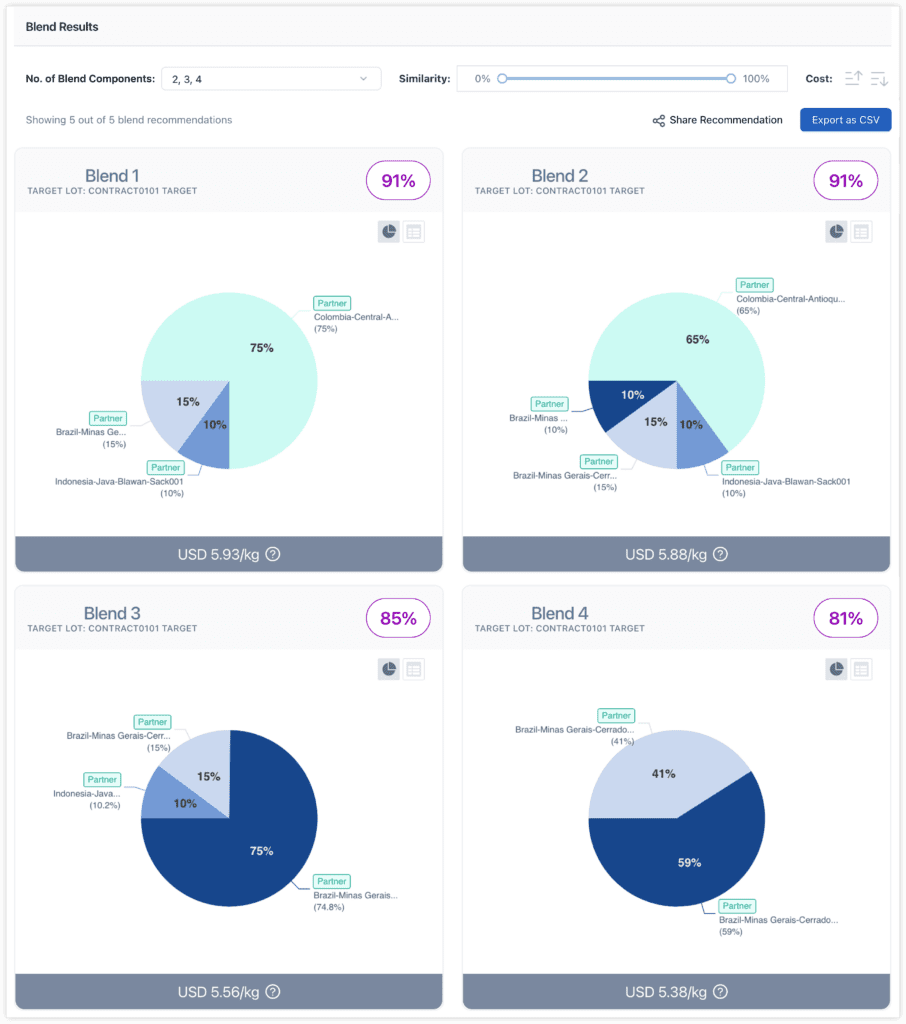

Blend

Tailored blend recommendations to achieve a target

Take the guesswork out of blend development with ProfilePrint’s AI-powered recommendation engine. By analysing your target profile, Blend suggests optimal combinations from your available inventory, before your experts test and approve the final blend.

Benefits:

- Accelerate blend development and time-to-market

- Balance cost and inventory, optimising resource allocation

- Combine AI-generated recommendations with human expertise to explore a broader range of possibilities

Use Case:

READY-TO-USE AI TOOLS

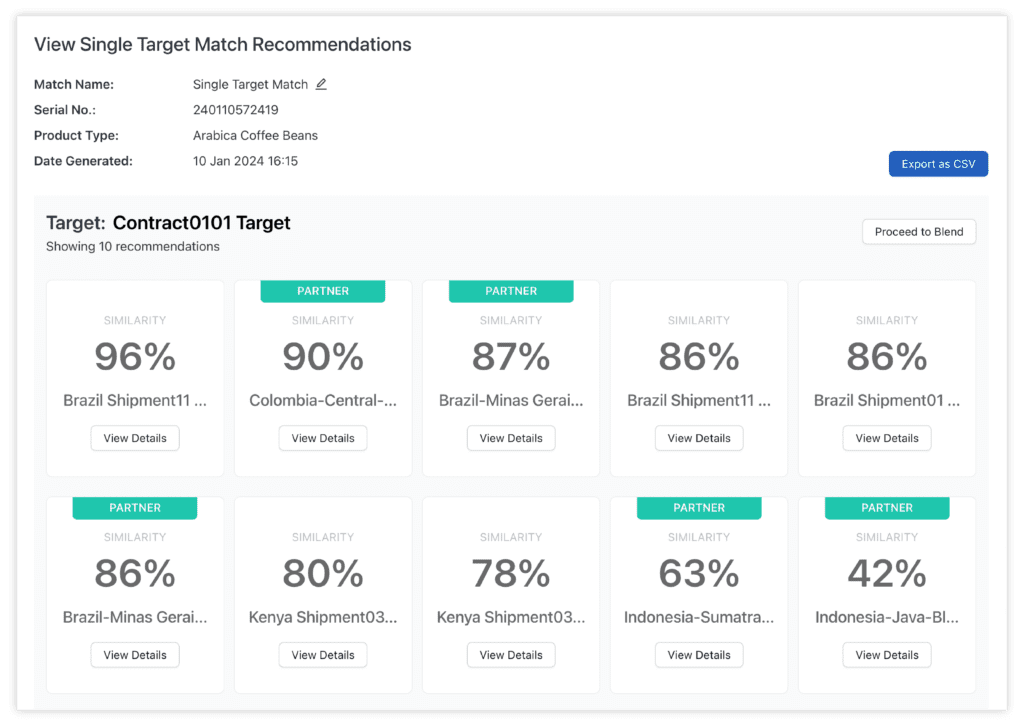

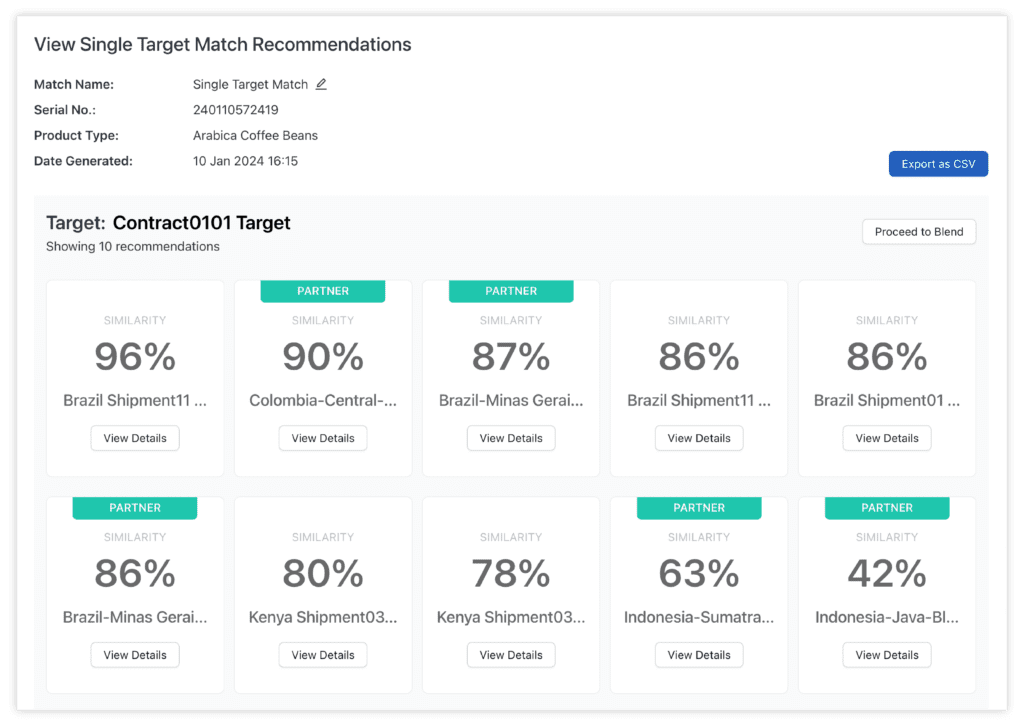

Match

BETA

Expedite discovery of new ingredients based on a target

Match analyses digital fingerprints to identify alternatives that align with your quality requirements. This tool expands your sourcing options and allows you to quickly pre-screen ingredients, empowering you to make more accurate purchasing decisions.

Benefits:

- Significant time and effort saved with target sourcing

- Buy more accurately, reducing risk of rejection

- Discover new sources you might not have considered

Use Case:

A premium tea supplier to global brands faced a critical supply chain challenge. Using Match, they rapidly identified alternative tea sources with matching flavour profiles. This enabled them to maintain uninterrupted supply to their global brand customers, compressing what would typically be weeks of sourcing into a streamlined process while maintaining their strict quality standards.

READY-TO-USE AI TOOLS

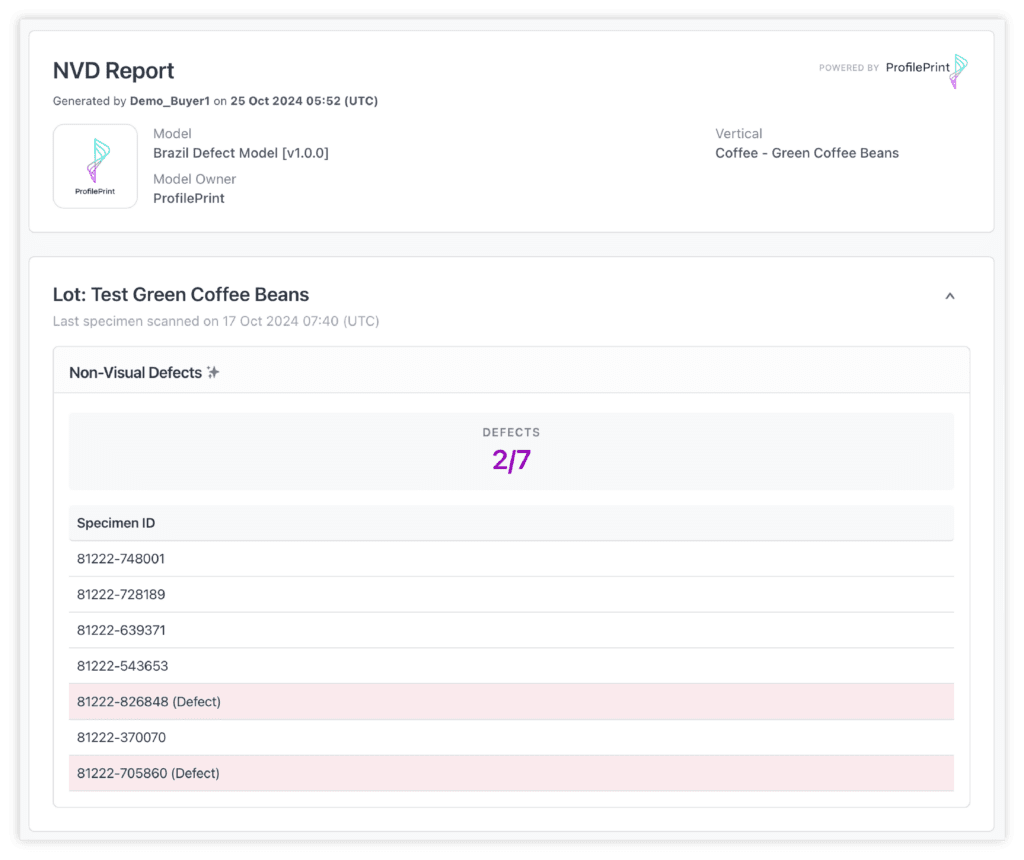

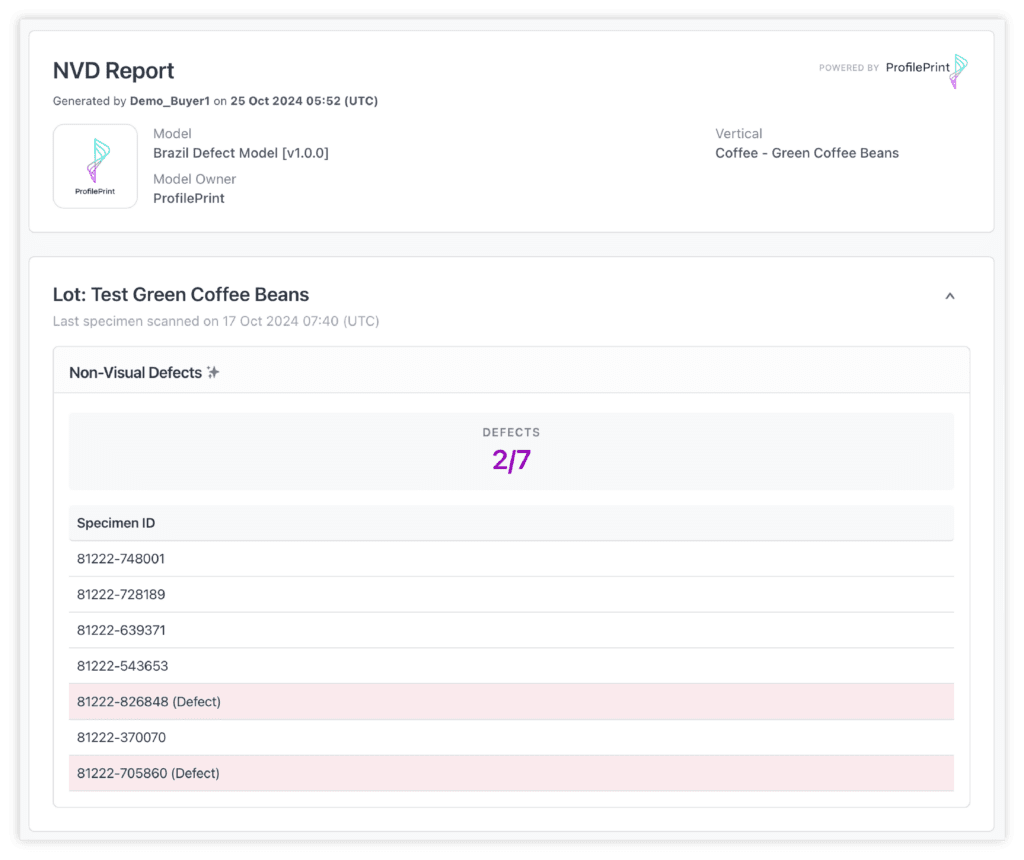

Non-Visual Defect (NVD) Detection

CURRENTLY ONLY AVAILABLE FOR COFFEE

BETA

Detect non-visual coffee defects instantly, without roasting or cupping

ProfilePrint’s proprietary scanning technology identifies sensory defects in green coffee beans by analysing their digital food fingerprints, instead of relying on visual cues or on traditional sensory evaluation which can be onerous and subjective. This AI-powered analysis learns from your sensory panels, and enables high-volume screening while maintaining consistency and accuracy.

Benefits:

- Rapidly screen and identify sensory defects without the need to roast or cup

- Buy more accurately according to quality requirements

- Process more samples while maintaining accuracy

Use Case:

A leading Brazilian coffee exporter faced quality assessment challenges during peak harvest season. Using NVD trained on just 58 samples (10 clean, 48 defective), they achieved 80% accuracy in identifying clean cups and 83% accuracy in detecting defects across four defect types. This pre-screening capability enabled their quality team to focus expertise on the most promising samples, significantly improving operational efficiency during harvest season.

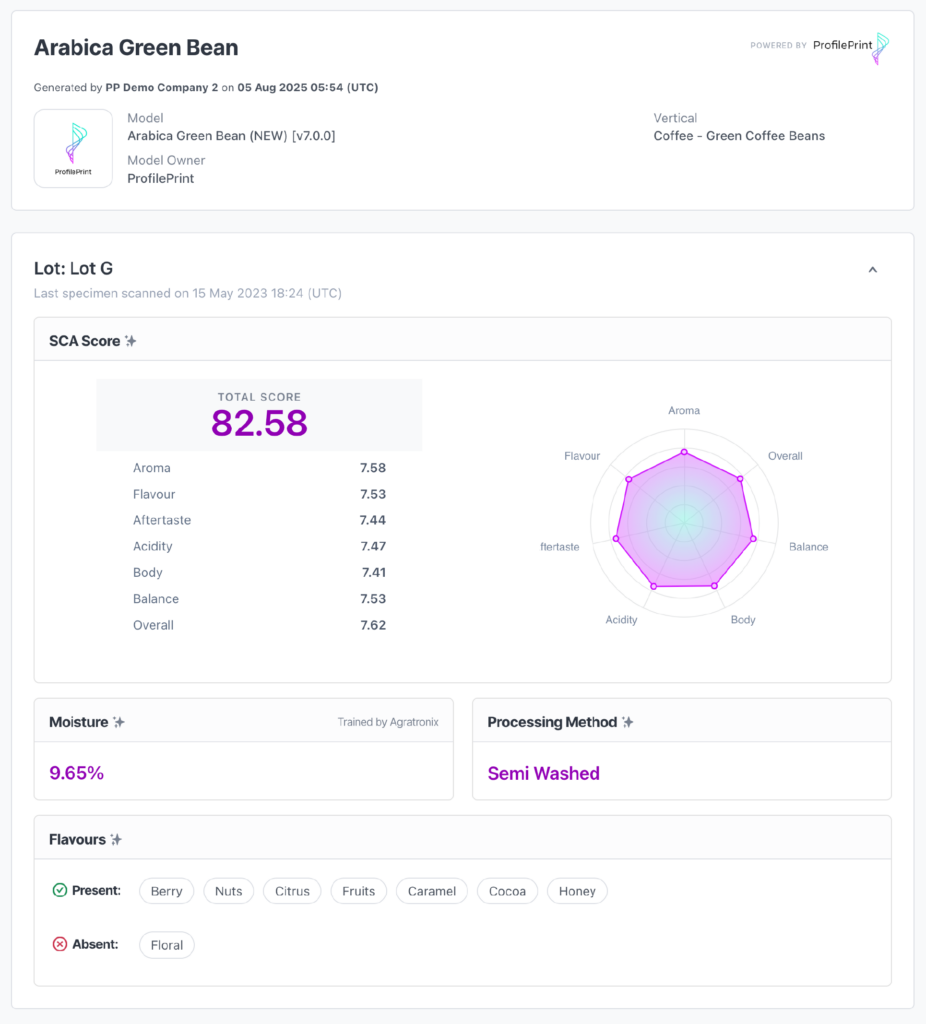

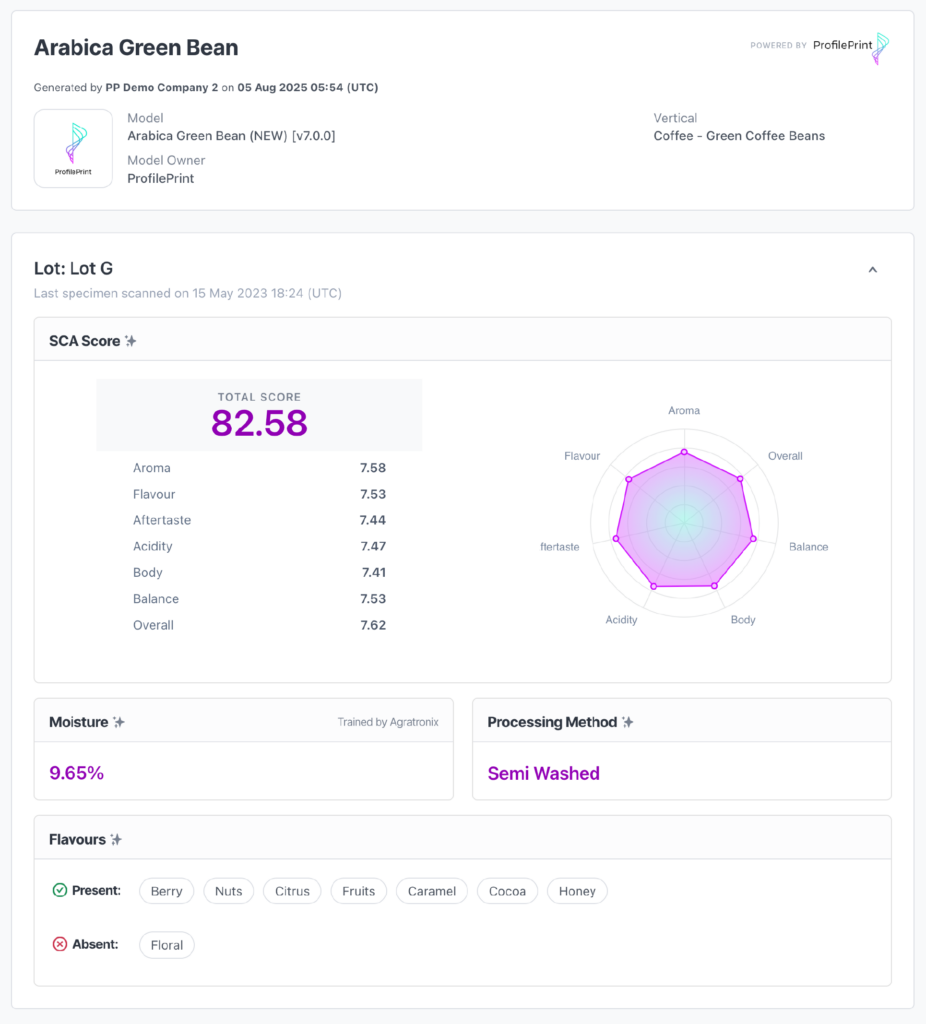

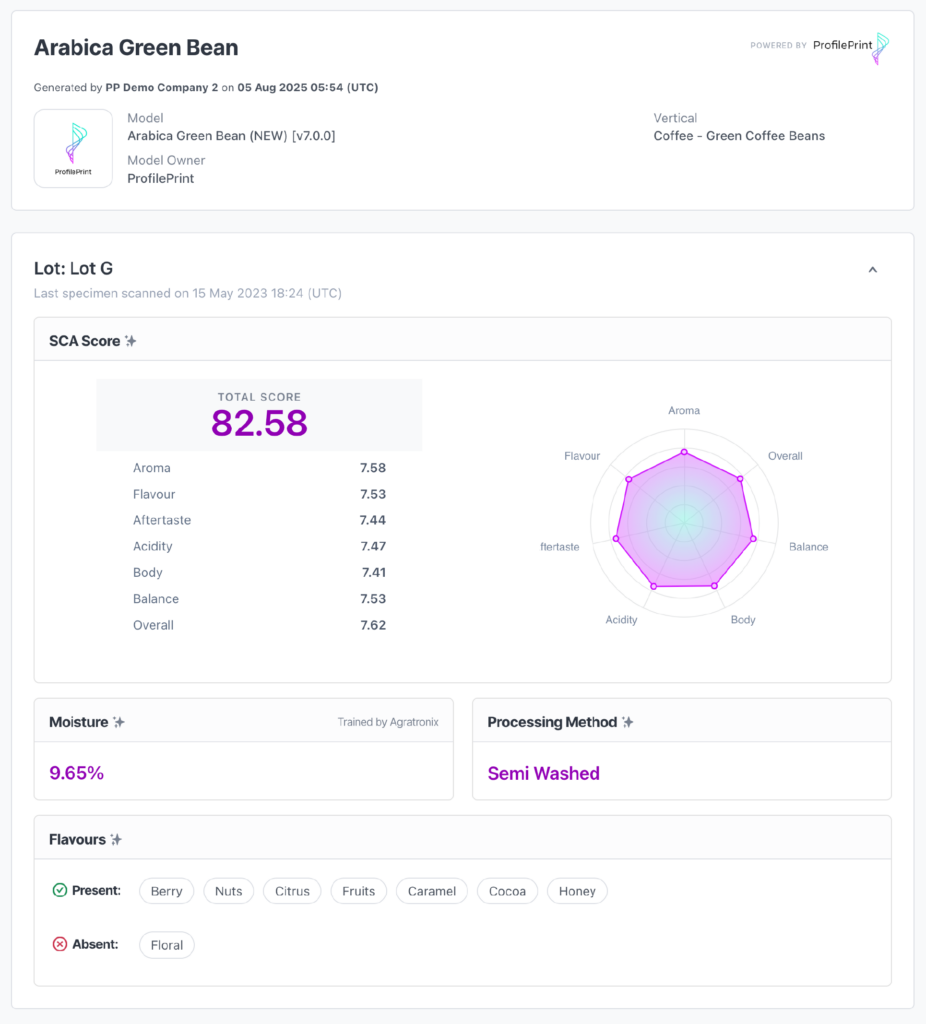

READY-TO-USE AI TOOLS

Plug-n-play models

CURRENTLY ONLY AVAILABLE FOR COFFEE

Ready-to-use AI models for immediate quality assessment

Gain immediate operational efficiency with pre-built ProfilePrint Plug-n-Play models to evaluate and screen ingredients against established benchmarks, or leverage partner-shared models to enhance understanding of quality standards and requirements.

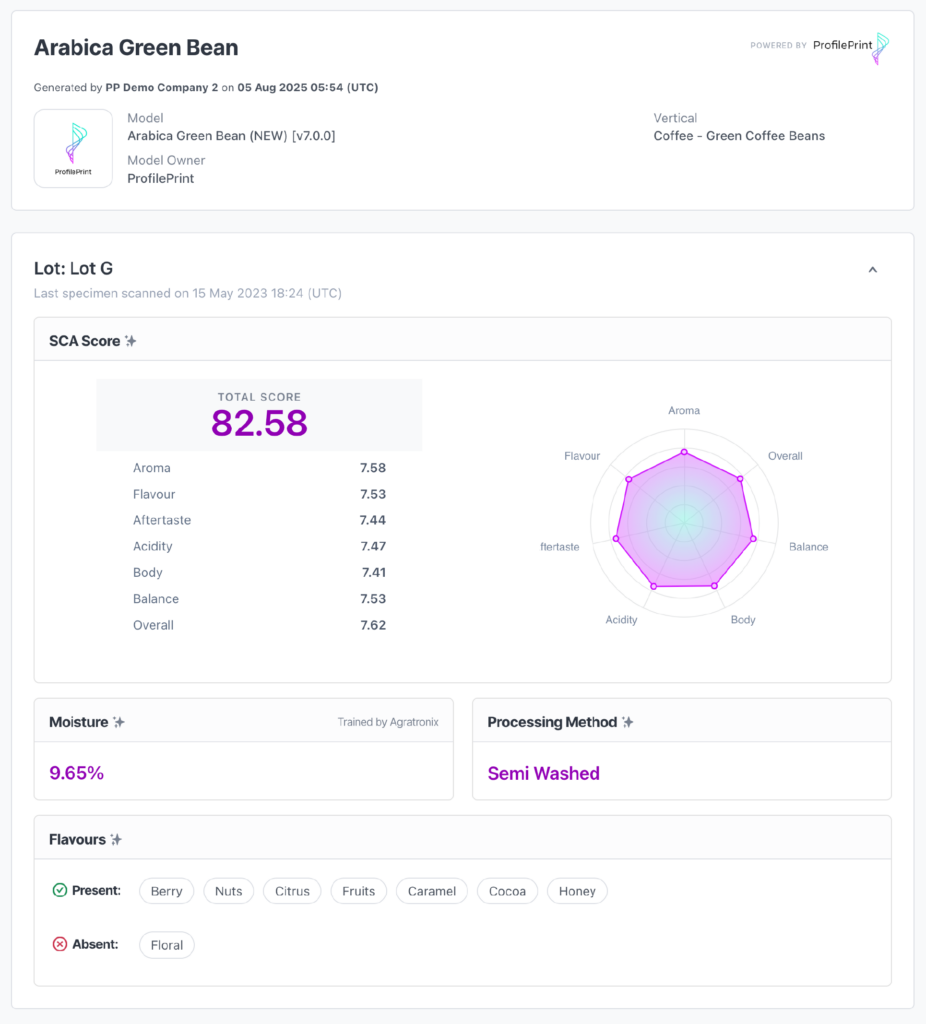

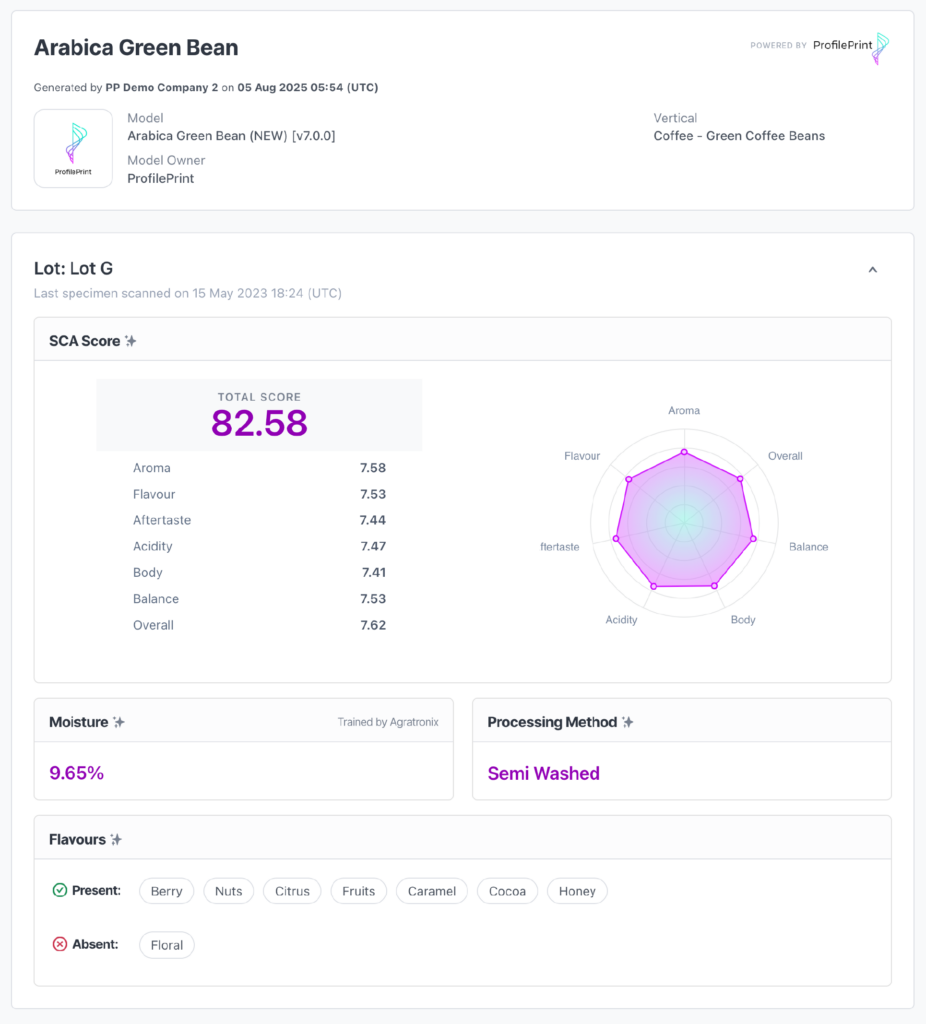

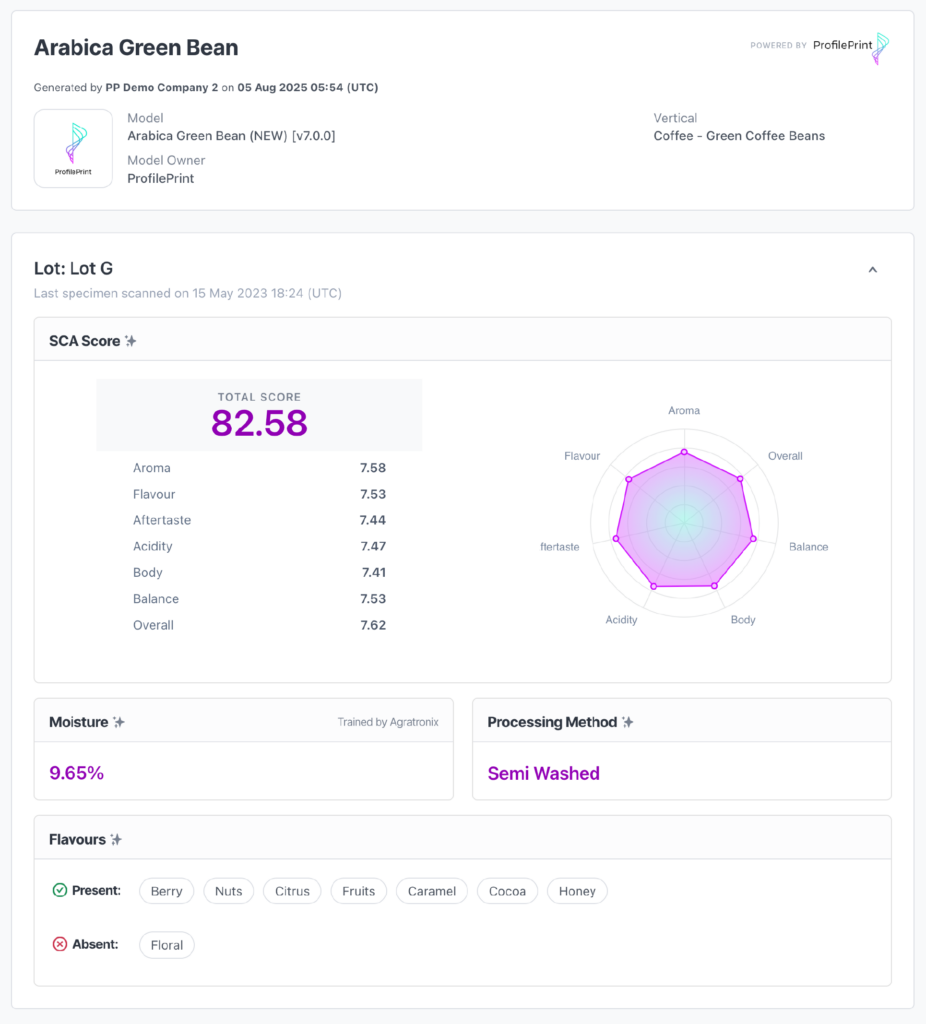

Specialty Arabic Green Bean Model

Cupping based on SCA standards

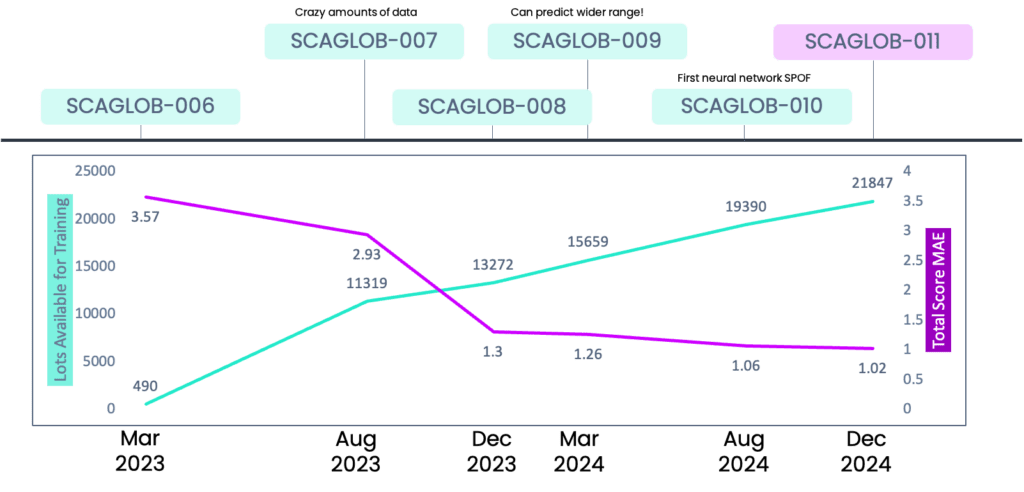

Access the collective expertise of Q-graders worldwide through our AI model, trained on over 25,000 specialty coffee samples from across the globe. This model delivers comprehensive SCA-based quality assessments without roasting or cupping, delivering data-driven evaluations that align with industry standards.

What it predicts:

- SCA score: Quality assessment based on industry-standard criteria

- Flavour profiles: Screen for specific flavour attributes like floral and caramel notes

- Additional quality indicators like moisture level and processing method

Our model draws from a diverse global dataset representing major specialty coffee origins, processing methods, and score bands.

Training foundation:

- Score bands: Ranges from 70 to 90, with the model showing strongest performance in the 80-85 score range

- Origins: Latin America (primarily Brazil and Guatemala, with additional representation from Uganda, Ethiopia, Kenya, Congo and Burundi), Africa (primarily Tanzania and Rwanda, with additional representation from Colombia, Honduras, Peru, Nicaragua, Mexico, El Salvador and Costa Rica), and Asia (primarily China, with additional representation from Vietnam, Indonesia and Papua New Guinea)

- Processing methods: Primarily Washed (84%), Natural (13%), and other specialty processing methods like Semi-washed, Anaerobic and others (3%)

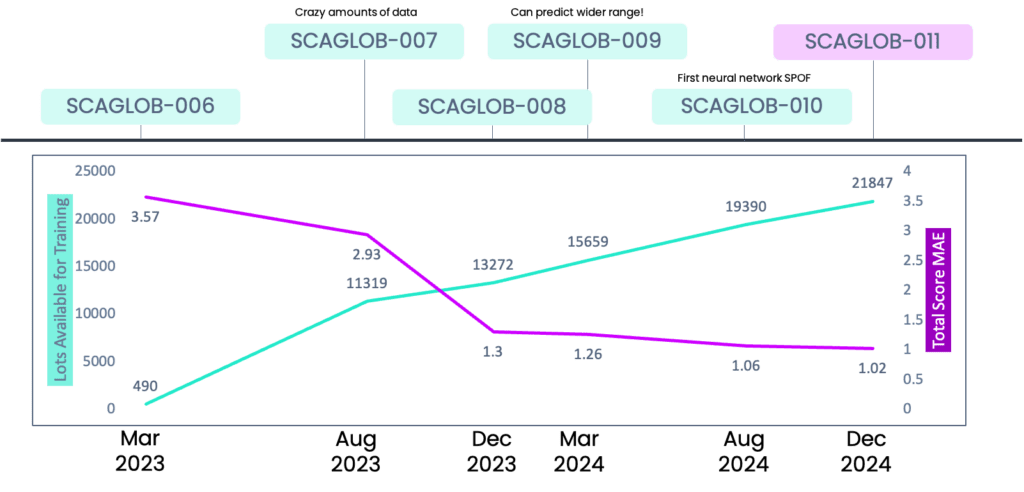

As of January 2025, the Specialty Arabica Green Bean Model maintains strong performance in the specialty coffee range with a MAE of 1.02.

Benefits:

- Predict coffee quality instantly based on SCA methodology

- Tap into expertise of Q-graders across the globe

- Focus your cupping efforts on ambiguous samples that are more nuanced

Use Case:

A specialty coffee importer screens over a hundred samples daily using the Specialty Arabica Green Coffee Model, reducing evaluation time by 80% while maintaining alignment with Q-grader assessments. This allows their team to focus cupping time on boundary cases and final selection decisions.

Coming Soon: Commercial Arabica Green Coffee Models

We’re expanding our offerings with origin-specific models designed for commercial coffee assessment. These targeted models will focus on Yunnan, Colombia, and Brazil origins, providing quality insights tailored to commercial coffee requirements and trading standards.

Sign up for our newsletter to be the first to know when these models are available.

ADVANCED AI TOOLS

Build-your-own Models

Custom models tailored to your requirements

Develop custom models to categorise ingredients, or predict characteristics calibrated to specific business requirements and standards. This tool transforms your expert knowledge and quality standards into automated assessment capabilities. With guided assistance, you can develop custom models that scale your expertise across your organisation.

Benefits:

- Improve speed and accuracy in ingredient assessment, streamlining decision-making processes

- Build custom AI models without requiring extensive data science experience

- Complement human expertise with high-volume sample processing, reducing sensory fatigue and substance exposure

Profile

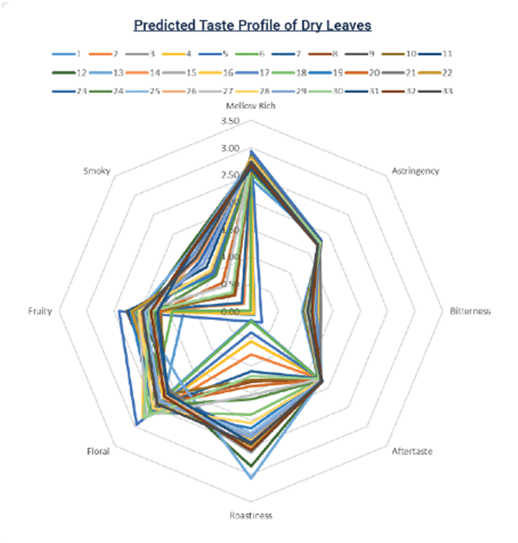

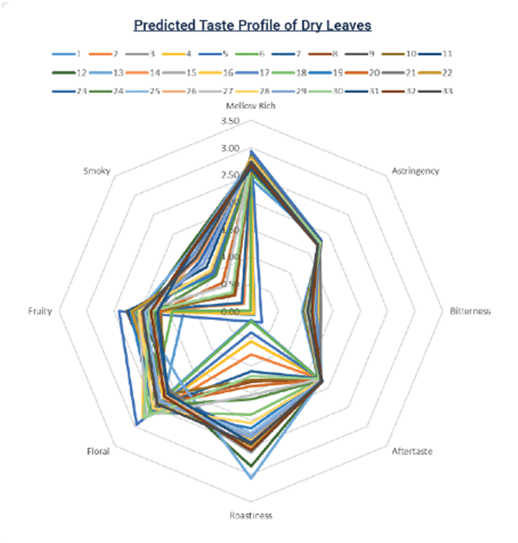

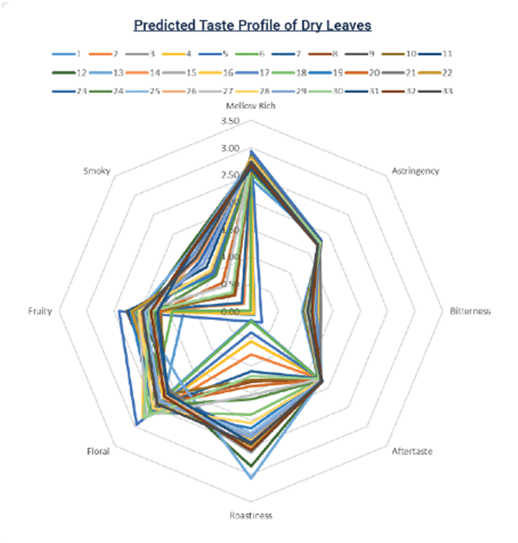

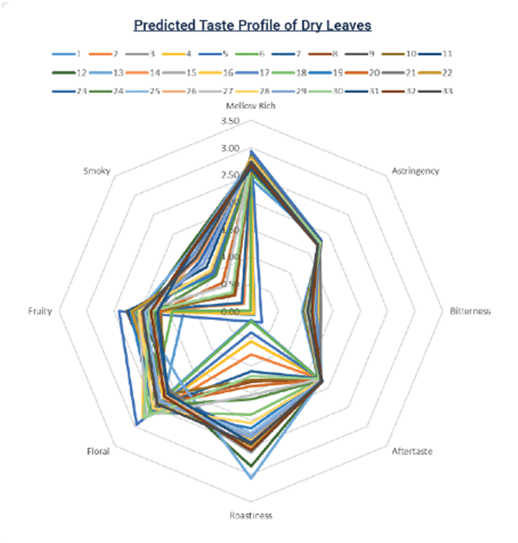

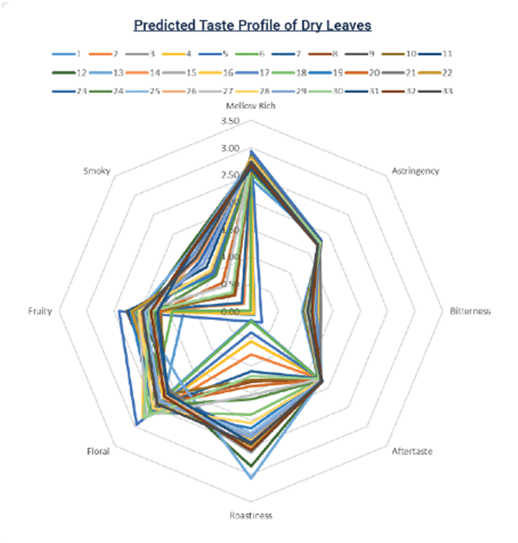

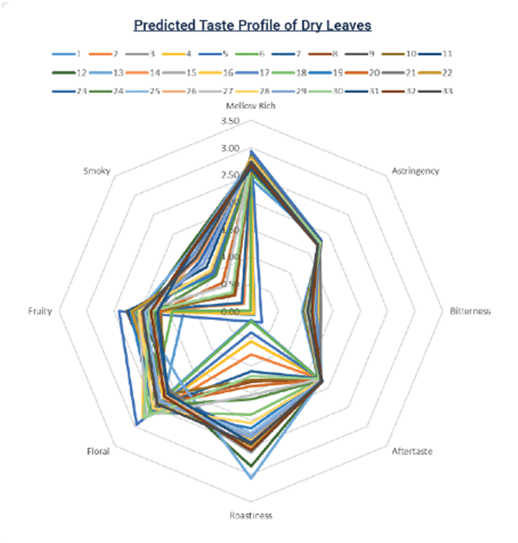

Scoring model to predict characteristics of an ingredient. Typically used to predict numerical scores or values for sensory parameters (e.g. aroma, aftertaste), moisture levels, and scores.

Use Case:

Beyond immediate efficiency gains, the model now serves as a valuable training tool for new tea tasters, ensuring consistency in quality assessment for years to come.

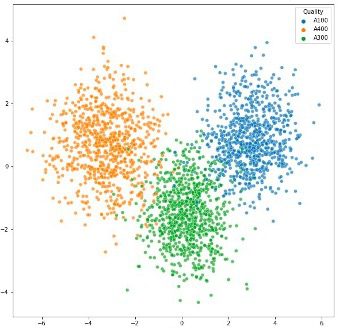

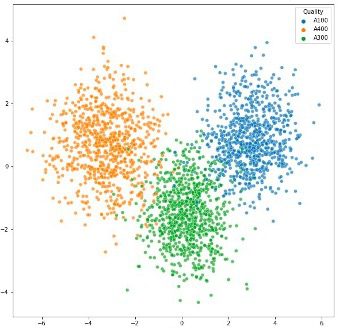

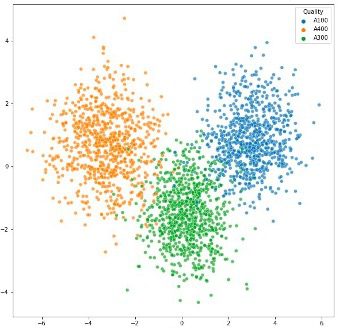

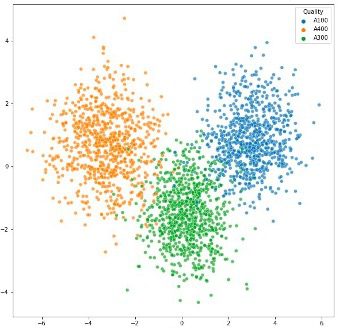

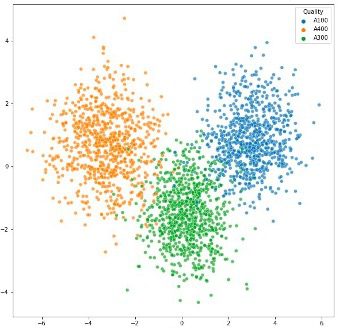

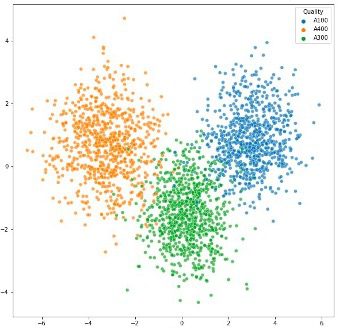

Classify

Sort and categorise ingredients. Typically used to assess quality (fail/pass), grade, defects, country of origin and so on.

Use Case:

A rice commodity trader needed to verify grain grades accurately to ensure fair pricing. Their custom Classify model successfully differentiated between three distinct rice grades based on digital fingerprints. This automated classification enabled rapid quality assessment at receiving, ensuring appropriate pricing and protecting margins through data-driven purchasing decisions.

ADVANCED AI TOOLS

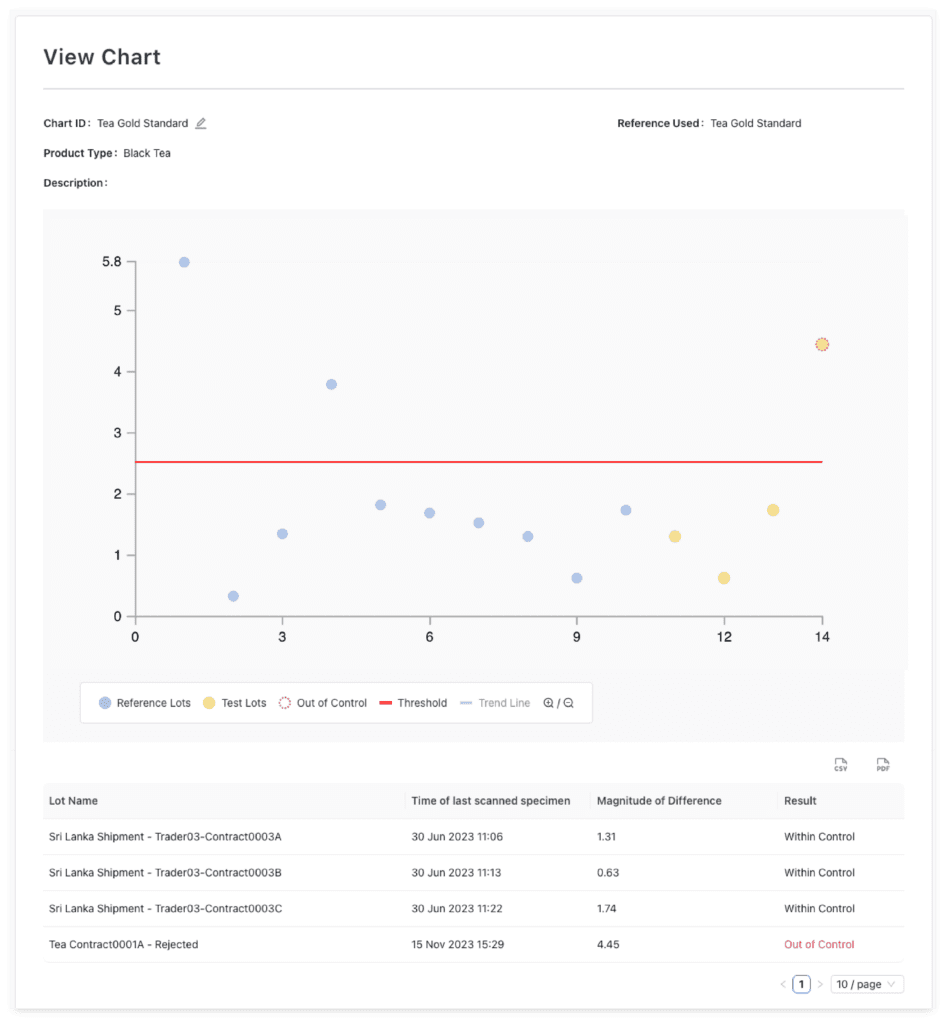

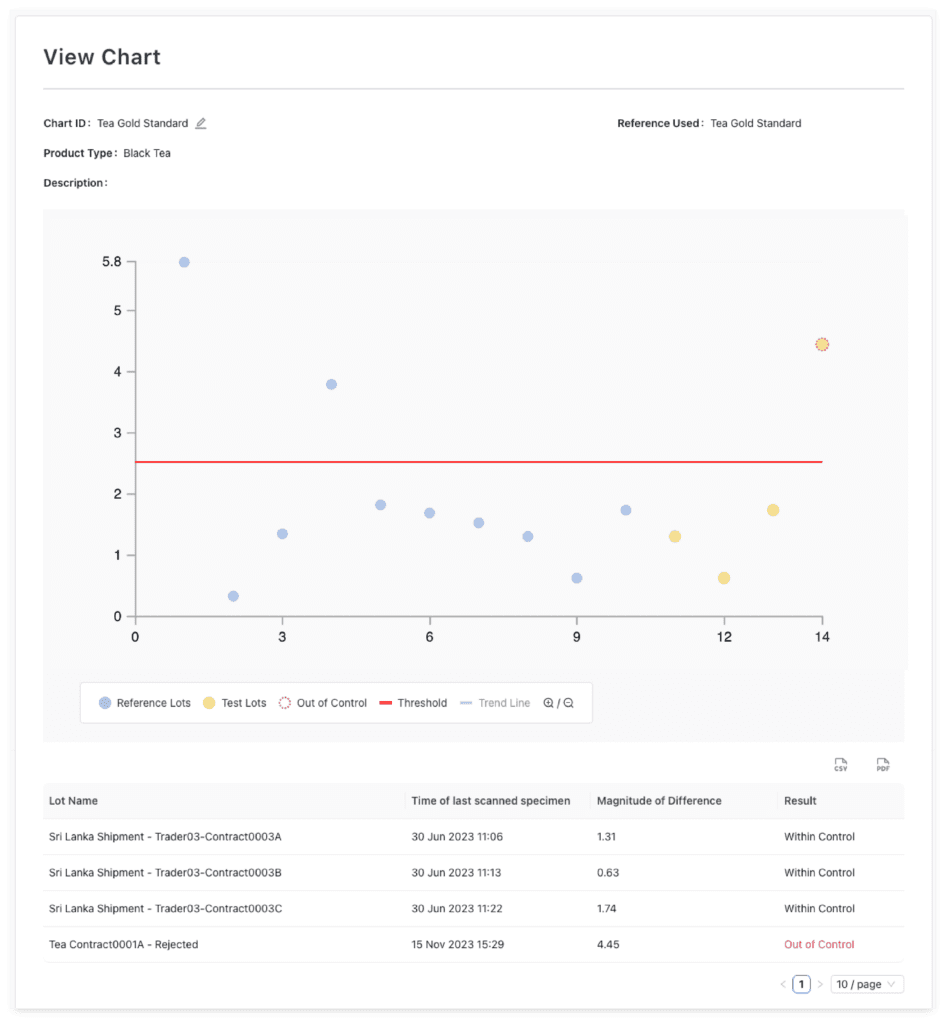

Monitor

Receive insights on quality variances within a process

Monitor tracks subtle variations and trends in your processes, enabling proactive quality management. This helps you maintain consistency while preventing quality issues before they escalate.

Benefits:

- Quickly identify product lots that fall outside acceptable quality ranges for further investigation

- Enhance team’s productivity by reducing manual inspections

- Detect quality inconsistencies early, preventing costly product recalls or wastage

Use Case:

A manufacturer implemented Monitor to track quality variations in their production line. ProfilePrint’s Monitor tool detected output that exceeded the quality threshold, and this was later found to be due to a formulation change. This allowed the production team to intervene before completing a full batch, preventing significant product waste and allowing our client to maintain consistent quality standards.

Get in touch

Speak to a member of our team to find out how ProfilePrint can help you transform your organisation today

Get in touch

Speak to a member of our team to find out how ProfilePrint can help you transform your organisation today

TRUSTED BY INDUSTRY LEADERS:

TRUSTED BY INDUSTRY LEADERS: